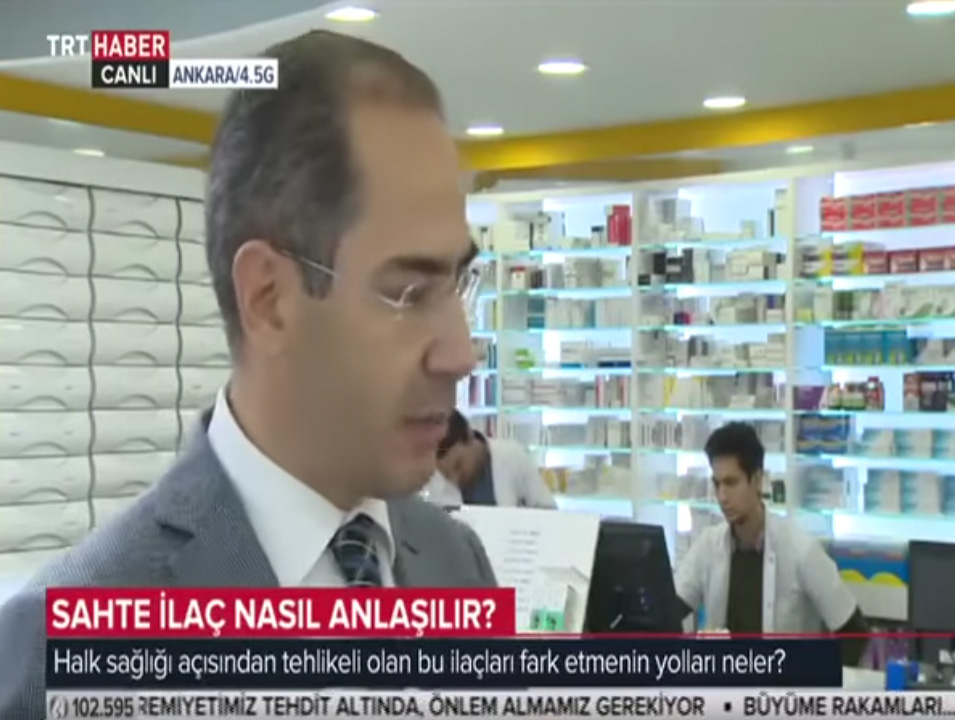

TİTCK Başkan Yardımcısı Fatih Tan Anlatıyor: Sahte İlaçlar Nasıl Anlaşılır?

4 Aralık 2017

Verimli Ürün Geri Çağırma İşlemi

8 Aralık 2017Product recalls are a process that all companies are trying to prevent, but need to be planned and implemented efficiently when needed, without delay or confusion.

How can we implement an efficient recall plan?

When in the process of recall, subjects that need to be taken into consideration can be divided into seven groups.* These areas must be taken into account in order to carry out the recall process efficiently. These seven topics are:

- Doing health-hazard analysis

- Determining what to do in a recall process

- Informing the authorities

- Making an announcement about the recall

- Keeping accurate records

- Working result oriented

- Determining exact end date of the recall belirlemek

When a recall is required and who can request the recall?

Simply, recalling is the only way to ensure the safety of a user when a product is found to be faulty for any reason. Recall may be voluntarily requested by the manufacturer or distributor, or may be requested by the authorities in case of emergency and necessity.

- Company’s recall after an exploration: During the company’s routine tests, the company may recall that the products do not comply with the standards.

- User’s recall: Recall may be required by the authorities to resolve the problem which come to light with the user complaints.

- Authorities’ recall after an inspection: Recall may be requested after an inspection if defective products is discovered by the assigned inspectors.

Health – Hazard Analysis Steps

- Determining of the cause

- Determining the side effects from the faulty products

- Preparing checklists for all the threats from the faulty products

- Checking the accidents and the diseases originated from the faulty products

- Determining the user profile and the region for the use of faulty products

- Determining the side effects from using the faulty product

After the health-hazard analysis is performed, how the user is affected and its results will have to be reported. Once the report is reviewed, solution to the said problems will be determined. After planing the solution all relevant departments should be contacted about it.

The plan should include the information of the drug to be collected, how the error occurred and the effects of the error, the amount of drug to be collected, the amount of wrong drug delivered and the direct users.

The level of recall is determined according to the information on the plan made and the results of the health-hazard analysis. The recall process can be at the manufacturer level, the pharmacy level or the user level.

Recall at the user level is the most serious type of recall and points out that there is a life-threatening use of the faulty medicine. Therefore, the plan should be executed post-haste and with cautious.

Before the plan is executed, it is absolutely necessary to inform the authorized people and send an announcement from the relevant channels. Recall processing systems, which may vary according to different countries, generally operate with the same logic. The records of the recall process reported to the authorities are kept to cover every faulty drugs. If the patient already used the faulty drugs, the necessary treatment should be provided.

Recall cannot be completed without the approval of the authorities. This means that even if all of the faulty drugs are seized and the safety of the patients is ensured, the procedure will be completed with a cancellation letter given by the relevant authorities.**

* http://www.pharmtech.com/…product-recall

** FDA, Guidance for Industry: Product Recalls